The Precision Craft of Diecasting: Revolutionizing Manufacturing

The Precision Craft of Diecasting: Revolutionizing Manufacturing

Blog Article

Diecasting is an important manufacturing procedure that entails forcing melting metal into a cavity with high pressure. The process is known for its ability to produce intricate shapes that have great precision and repeatability, making it an essential tool in many sectors. From aerospace and automotive to consumer electronics, household appliances and more, diecasting plays a crucial role in creating products that can meet the strictest standards of quality and performance. This article focuses on the intricacies of diecasting by focusing on its advantages, processes as well as applications.

The process of diecasting starts by creating a mold, known as a die. The mold is crafted from hardened steel that can withstand extreme pressure and temperatures. When the mold is ready the metal alloys like magnesium, aluminum, zinc or copper are heated until they are melted. This molten metal is then injected into the die at great pressure. It fills all parts of the mold including intricate sections and walls that are thin. Pressure is maintained until the material has solidified, and at that point, the mold is opened, and the part that has been formed will be ejected. This high-pressure method ensures that your final product is exact, with minimal need for any additional finishing or machining.

One of the most significant advantages of diecasting is its efficacy in mass production. When dies are manufactured and shaped, they are able to create thousands of identical parts with minimal variation. This degree of precision is necessary for all industries that need large quantities of consistent components. Diecasting is also known for its high efficiency of materials. It produces little waste, as excess metal is re-usable during subsequent casting cycles. This reduces not just cost of materials but also helps to promote sustainable manufacturing practices by minimizing waste and conserving resources. A combination of efficiency, high speed, and material efficiency makes diecasting a desirable option for manufacturers aiming to optimize their production processes.

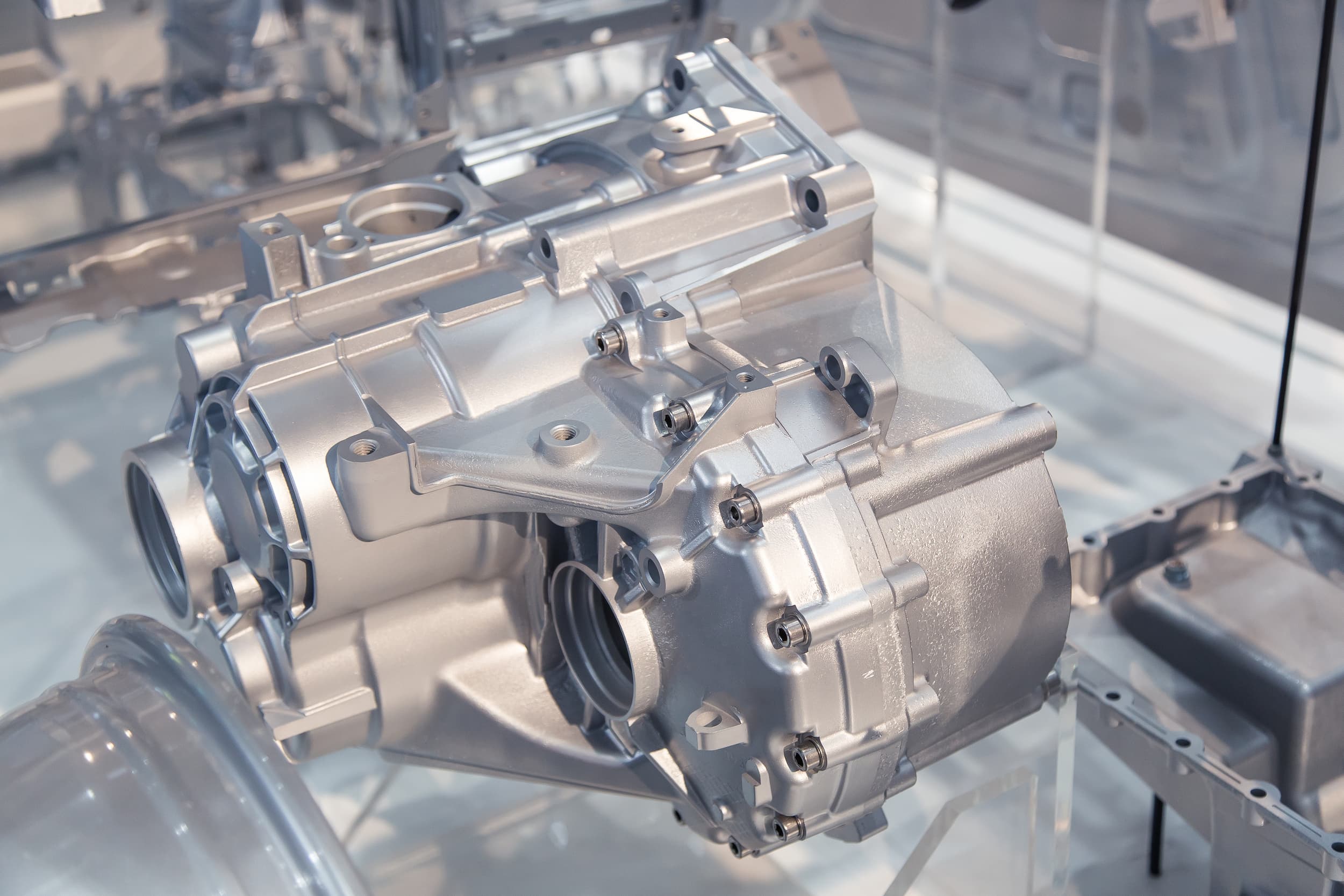

Diecasting is extensively used in many industries due to its versatility and range of materials used. In the automobile industry diecast components are crucial for producing components such as engine blocks, transmission cases and structural pieces. The aerospace industry relies on diecasting to create lightweight, high-strength parts that can endure the harsh conditions of flying. In electronics for consumers, diecast components are used for frames and housings that offer high-quality and precise devices. Diecasting's flexibility is evident in applications such as the medical, telecommunications, and power tools industries and demonstrates its vast use and significance. To find further information please Read More Here

Diecasting's flexibility extends into a variety of applications across different sectors. For instance, in the automobile industry diecast parts are essential to the design of motors, transmissions and structural elements, contributing to the production of less weight and more efficient vehicles. For electronics the use of diecasting can be used to manufacture heat sinks, connectors and housings, ensuring optimal thermal management and durability for electronic devices. Consumer goods also benefits from diecasting, with applications that span from household appliances to power tools, toys and even power tools. The process's adaptability to various metals as well as its capability to make parts with complex patterns make it suitable for numerous kinds of products, each benefitting from the advantages that diecasting offers.

Diecasting is a crucial manufacturing technique that blends high-quality, efficient as well as versatility. Its capability to make intricate, high-quality products with outstanding mechanical properties make it indispensable to many sectors. The efficiency of diecasting for mass production, together with its material and price benefits, underscores its value in modern manufacturing. In the era of high-performance and durable components continues to grow, diecasting will remain the foundational technology for advancement and helping in the creation of innovative products that satisfy changing demands of the marketplace. Through continuous advancement and use diecasting illustrates the connection between engineering excellence as well as manufacturing experience, strengthening its role in the future of industrial production.